PIC Packaging Services

From first prototypes to scalable solutions

Why PIC Packaging Matters

A photonic chip is a remarkable piece of technology, but without smart packaging it remains a laboratory experiment. Photonic Integrated Circuit (PIC) packaging is the process of connecting the photonic chip to the outside world – through fibers, electronics, and housing – so it can reliably perform in real-world environments.

At PhotonFirst, we help organizations take their innovations out of the lab and into the field. From the first prototype and proof-of-concept to a ruggedized module that keeps working under extreme conditions, our packaging services are designed to make photonics practical, scalable, and dependable.

Photonic Integrated Circuits allow for smaller, faster and affordable solutions

Our Approach: Flexible and Scalable

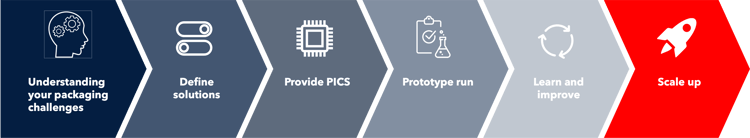

Many providers focus either on prototyping or on volume manufacturing. At PhotonFirst, we deliberately do both. We know that most projects start small – a handful of packaged samples for R&D – but need to grow into scalable industrial solutions. That is why our services are designed so you never have to start over when scaling up.

What sets us apart – we developed our own PIC based sensing solutions following the exact same path from prototyping to small series:

- End-to-end service – From design and prototyping to small-series production

- Proven track record – Numerous unique packaging designs developed for aerospace, energy, and infrastructure applications

- Cleanroom manufacturing – ISO 14644-1 Class 8 environment with strict ESD controls

- PIC integration by default – Compact, lightweight, and scalable solutions

- Co-development mindset –

- Option A: Your package is developed to your spec with our industrialization know-how, ensuring it fits the exact application

- Option B: Choose from a wide range of standard packages for a quick start

Today’s prototype can evolve into tomorrow’s industrial module

Our PIC Packaging Capabilities

PIC Package Design

Design

PIC Testing

PIC Testing

Die-bonding

Die-Bonding

Wire-bonding

Wire-bonding

Fiber-bonding

Fiber-bonding

System Integration

System Integration

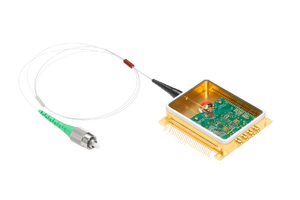

Our PIC Packaging Portfolio

PhotonFirst offers a broad portfolio of PIC packaging options, tailored to your project stage and application:

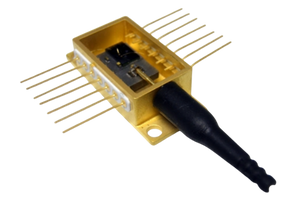

- Standard Packages – Fiber-coupled, compact solutions for laboratory testing and rapid prototyping.

- Ruggedized Modules – Shock- and vibration-resistant, qualified for aerospace and defense environments.

- Miniaturized Packages – Ultra-compact, lightweight solutions for drones, medical devices, and portable systems.

- Custom Packaging – Fully tailored designs co-created with customers to meet unique optical, thermal, or mechanical requirements.

GP01/02/03

- Designed for flexibility

- Fast & affordable prototyping

- 40GHz maximum frequency

GB01

- High speed (4x RF)

- Fast & affordable prototyping

- 50GHz maximum frequency

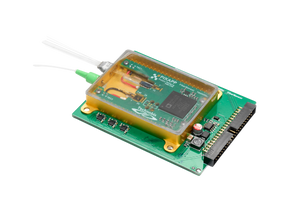

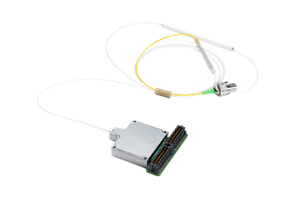

SIP01

- Opto-electric, multi-chip integration

- Miniaturizing functional complexity

BP01

- Standard form factor

- High volume, single function

- 10 MHz maximum frequency

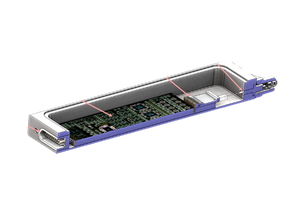

XE01

- Extreme harsh environment

- Complete system OEM integration

- 100kHz maximum frequency

CU01 ..x

- High volume, fit for application

- Multi-purpose OEM integration

- Customizable maximum frequency

Key benefits of selecting PhotonFirst as your Packaging Partner

-

High mix, from low volume to 100’s & 1000’s

-

Rapid prototyping to rapidly learn and improve designs

-

Complete (custom) package development

-

Designed for harsh environments

-

Low-lightloss fiber to chip coupling

Tools to get you started

Frequently asked questions about PIC Packaging

Achieving stable and precise fiber-to-chip alignment at the nanoscale. At PhotonFirst, we solve this with high-precision assembly in cleanroom conditions.

Because we don’t just deliver a package – we deliver a scalable path from prototype to industrial module. In addition, we deliver:

- High reliability: built in cleanroom conditions with strict quality and ESD standards

- Miniaturization: PIC technology enables ultra-compact, lightweight designs

- Cost efficiency: from €50k prototypes down to ~€1k industrial units through volume scaling

- Flexibility: standard, ruggedized, miniaturized, or fully custom – all possible.

Absolutely. Most projects begin with a proof-of-concept. From there, we work together step by step towards a robust industrial solution.

Applications of our PIC Packages

Railway & infrastructure

Embedded PIC sensors in bridges, tunnels, and quay walls, e.g. for the City of Amsterdam

Maritime & offshore

Precise monitoring for condition-based maintenance of machinery and subsea assets - Feasible with PIC packaging

Our Customers

Innovation Partnership Programs